articoli

If you have a basic understanding of valves you probably know ball valves, one of the most common types of valves nowadays. A ball valve, as a general rule but not always, is a quarter turn valve with a perforated ball in the middle which allows fluid to pass. These valves are known to be durable with excellent shutoff, but they do not always offer very precise flow control.

As we explained in the previous article , it is essential to eliminate the existing air inside a steam installation to maximize heat transfer. In this article we will explain the relationship between the density of air and steam, and later we will analyze how it affects the installation of air vents.

Has it ever happen that the steam pressure of your process is correct but the temperature is lower? Air can mix with steam at start-up or during operation, which reduces the pressure of the steam and therefore its temperature, thus impairing total heat transfer . That phenomenon was demonstrated by John Dalton and his law of Partial Pressures The Partial Pressure Law states that when different types of gases are mixed, the total pressure of all gases is equal to the sum of the partial pressures of each gas. Total Pressure = P1 + P2 + P3 ... Therefore, if our installation contains other types of gases besides steam, these gases will affect the total pressure indicated on the pressure gauge or pressure transmitter.

In steam demanding industries, the steam generated is normally locally reduced at the points of consumption. There are several reasons why steam pressure is reduced at points of consumption, such as: the reduction of costs when installing smaller diameter pipes, accessories and valves; or also on many occasions, the steam consuming equipment does not tolerate high pressures or simply must work at a fixed pressure which is below the steam generation pressure. We all know that if we reduce the steam passage section, its pressure decreases at the same time that its speed increases. The most basic way to reduce pressure is to install a manual seat valve in a partially closed fixed position, or insert an orifice plate to reduce the cross section. However, if we use any of these methods to reduce the pressure, any fluctuation in the steam flow upstream (before the reduction of the section) will be reflected downstream (after the reduction).

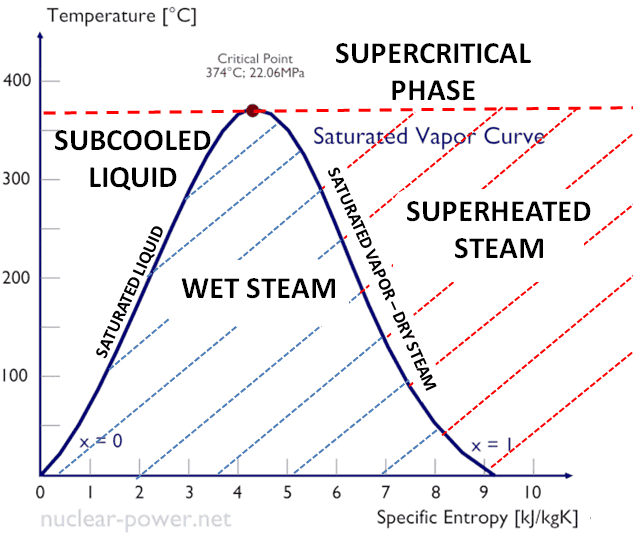

Did you know that steam boilers do not generate 100% dry saturated steam? When a boiler heats water, the bubbles that break the surface of the water incorporate small droplets of water into the Steam stream and this causes the steam flow to be partially wet (wet steam) due to the presence of liquid.

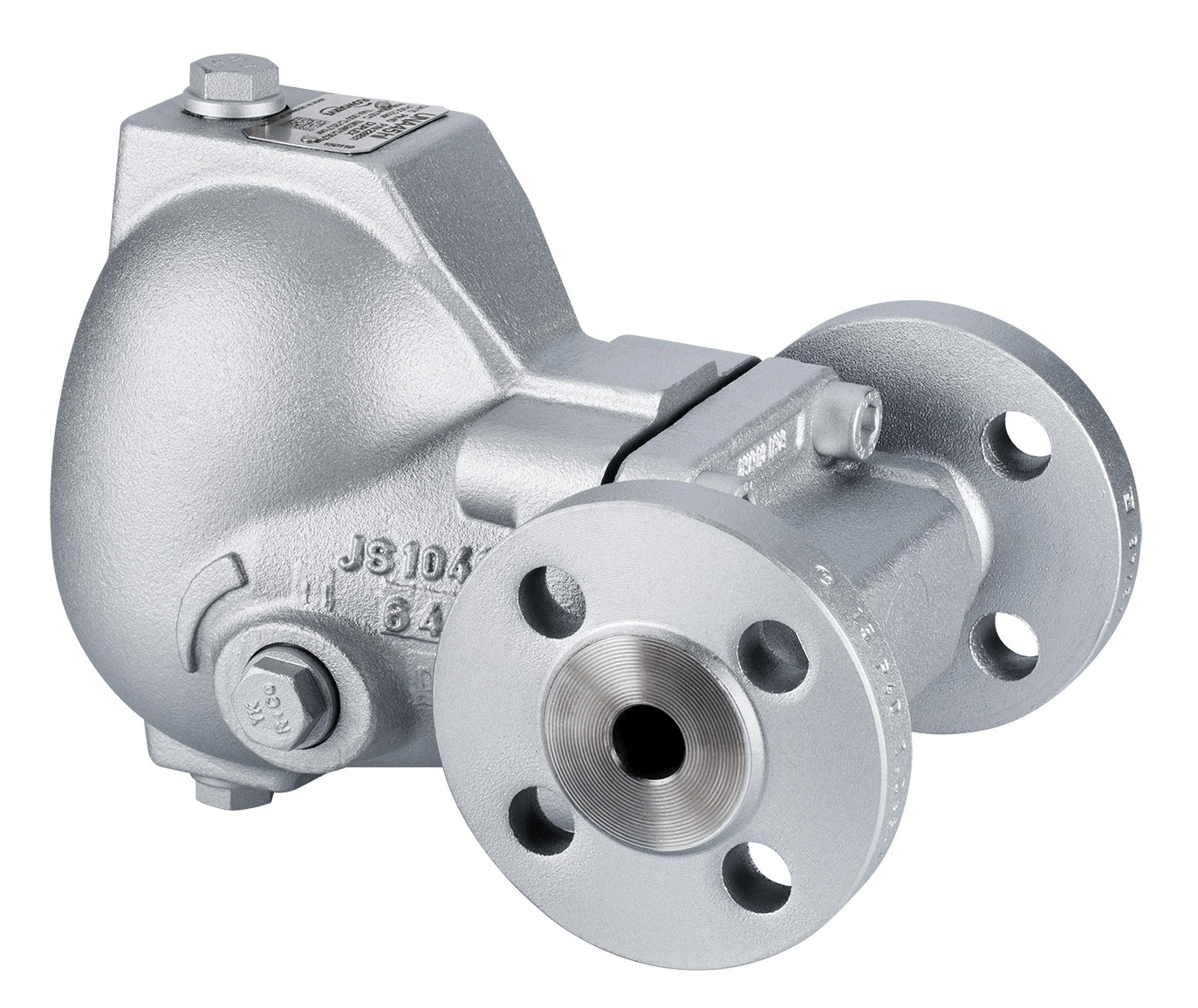

The partial revaporization that the condensate sufferss when it is discharged into the Steam Trap is one of the causes that produces serious problems of various kinds, the following are the most common: Operation Problems » Line cooling and reduced efficiency in heating processes » Creation of Thermal Water Hammers » Difficulty regulating heat exchange processes » Solidification of viscous products in lines and process equipment Energy and Enviromental Problems » Increased Steam Leaks » Increase in atmospheric CO2 emissions » Difficulty in recovering condensate and residual energy » Increased noise and humidity in the process units Inspection and Maintenance Problems » Steam Traps inspection difficulty » Increased erosion in condensate return pipelines » Increased internal wear on Steam Traps » Breakage of elements and gaskets caused by water hammer » Increased corrosion due to wetter environments All these problems generally have as a common cause: the rise of the back pressure in the condensate return tank , originated as a consequence of the enormous increase in specific volume that the condensate suffers when its partial evaporation occurs in the Steam Trap discharge.

The pressure and the temperature of the Saturated Steam are related in such a way that each pressure corresponds to only one saturation temperature. This relationship as well as energy content (enthalpy), specific volume and other properties of the steam can be obtained by consulting the Saturated Steam table or the Steam Saturation curve. In the Saturated Steam table, which you can find in our downloads section, it is observed that sensible heat (heat of boiling water) increases when the pressure also increases, while latent heat (heat of evaporation or heat given up in the condensation) decreases when the pressure increases.

Due to the high request of many of you, following the last published article - Float type Steam Trap or Thermodynamic Trap? - In this week's article we will explain how to correctly size a Float type Steam Trap. First of all we must understand the Float type Steam Trap as a liquid level regulation valve.