Issues caused by Flash Steam

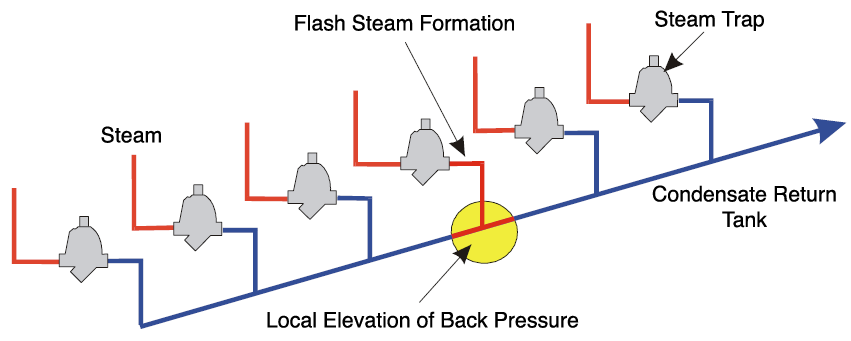

The partial revaporization that the condensate sufferss when it is discharged into the Steam Trap is one of the causes that produces serious problems of various kinds, the following are the most common:

Operation Problems

» Line cooling and reduced efficiency in heating processes

» Creation of Thermal Water Hammers

» Difficulty regulating heat exchange processes

» Solidification of viscous products in lines and process equipment

Energy and Enviromental Problems

» Increased Steam Leaks

» Increase in atmospheric CO2 emissions

» Difficulty in recovering condensate and residual energy

» Increased noise and humidity in the process units

Inspection and Maintenance Problems

» Steam Traps inspection difficulty

» Increased erosion in condensate return pipelines

» Increased internal wear on Steam Traps

» Breakage of elements and gaskets caused by water hammer

» Increased corrosion due to wetter environments

All these problems generally have as a common cause: the rise of the back pressure in the condensate return tank, originated as a consequence of the enormous increase in specific volume that the condensate suffers when its partial evaporation occurs in the Steam Trap discharge.